Golden Triangle Polymers Spurs Economic Development in Orange County

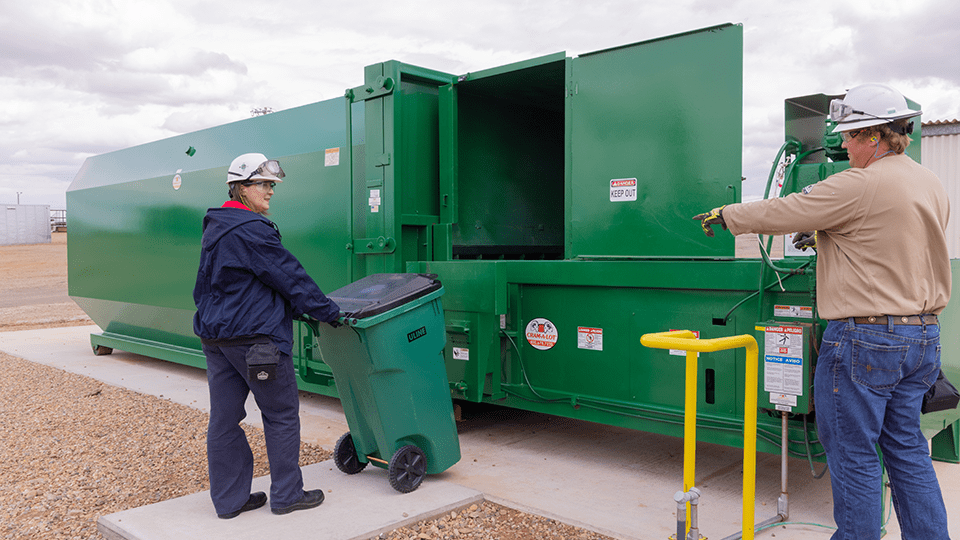

Orange County, Texas, is in the midst of a major transformation, thanks to the substantial investments being made by major industrial projects like Golden Triangle Polymers, said Megan Romero Layne,